- Slide of disc-holder slips on guides in hardened steel, cold-drawn, in class of precision H and sliding-block with recirculating balls pre-loaded for the elimination of the mechanical clearance.

- Positioning with pinion- helical rack system of precision and epicycle reducer with 0 clearance (Axis X).

- Sliding of the bridge on guides in hardened steel, cold-drawn, in class of precision H and sliding-block with recirculating balls pre-loaded.

- Positioning with 2 motors in electrical-axis with pinion- helical rack system of precision and epicycle reducers with 0 clearance (Axis Y).

- Sliding of head-holder on over-dimensioned chromed cylinder.

- Positioning with system screw-nut with recirculating balls pre-loaded and epicycle reducer with 0 clearance (Axis Z).

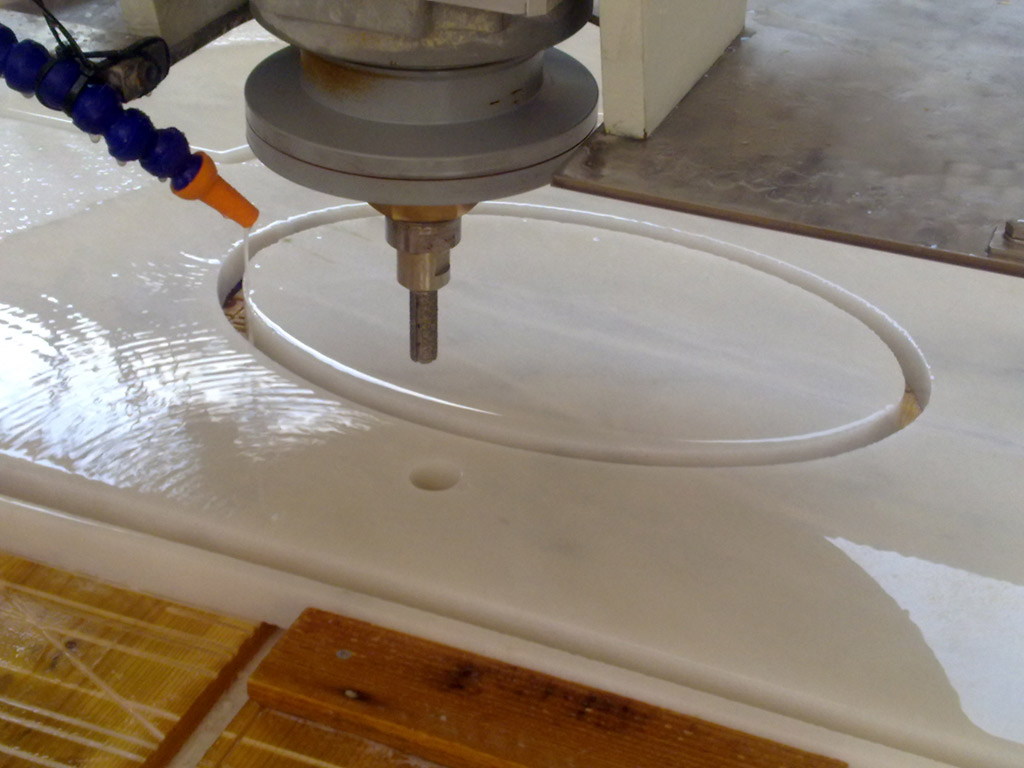

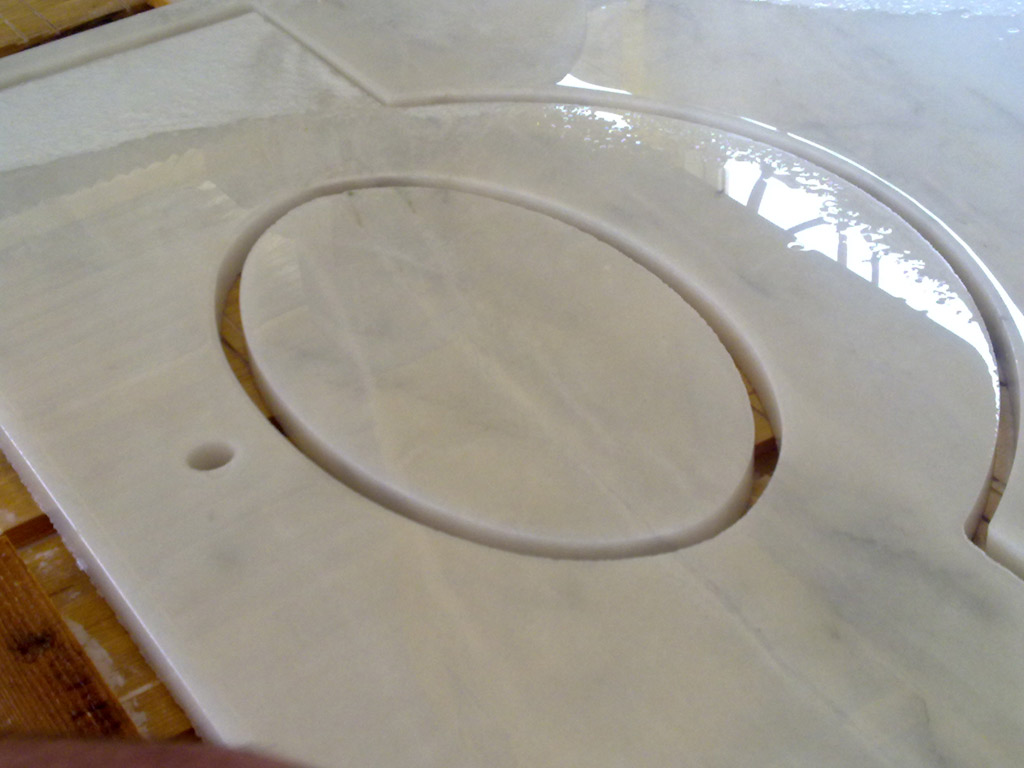

- Spin of the head ± 185° with reducer of high precision with eccentrics with 0 clearance (Axis C).

- Spin of the mandrel 0°-90° reducer of high precision with eccentrics with 0 clearance (Axis A).

- All the drives complete with elevated inertia BRUSHLESS motors, digitally controlied with system CAN-BUS.

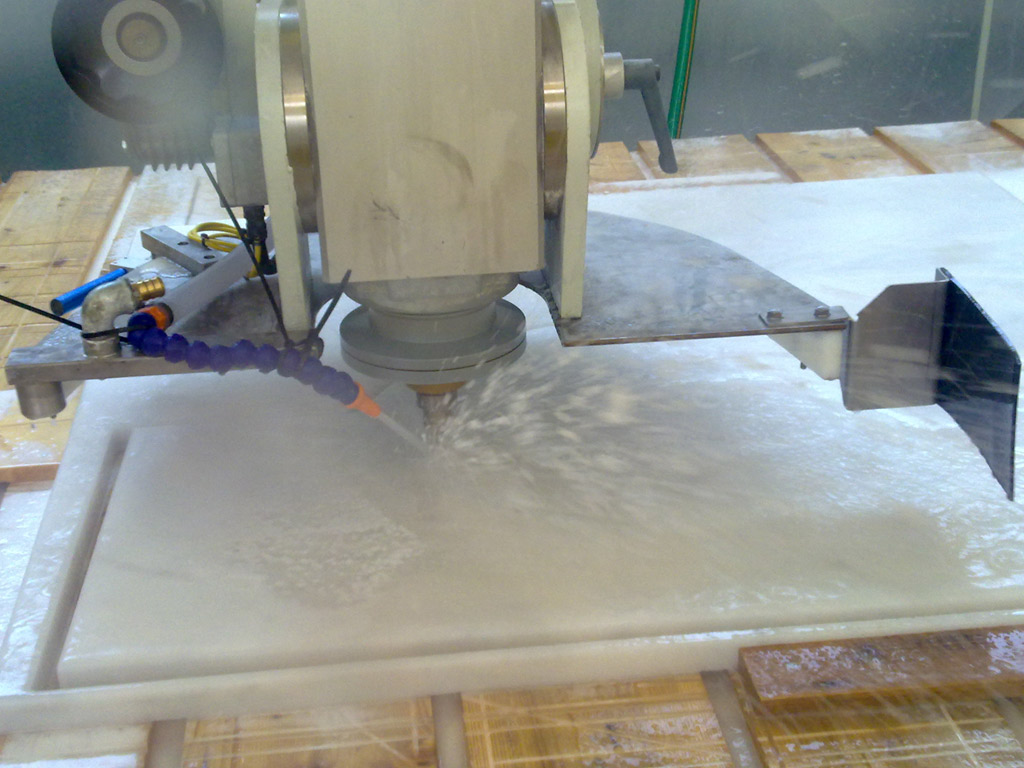

- Disc motor, power 11 kW, directly connected to the biade, electronic control of rotation speed by mean of INVERTER.

- Possibility of tilted cut in small steps obtained with interpolation of the axis horizontal and vertical.

- Switchboard with isolation IP 55 at the right of the machine and outside of the foundation wall, with the general switch and block door. In the control panel are grouped the contactors with the relative thermal protections, the drives and the electronics controis, the complete CNC control while the Touch screen panel and the keyboard are positioned in a remote pendant box.

- Laser beam facilitates positioning of biade on cutting line.

- Water pressure switches stops machine, if cooling water insufficient.

- Tools are protected by an electronic ammeter to prevent use above preset values.

- Refrigeration pipes and electrical wiring protected in plastic cable trailer chain.

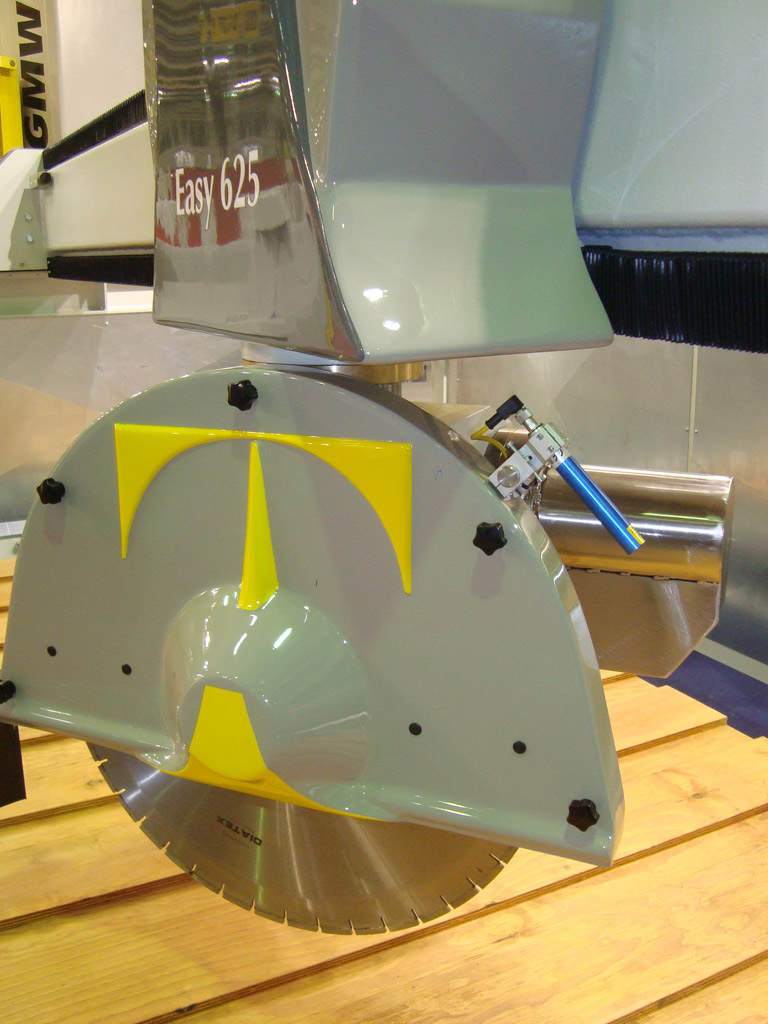

Easy 625

5 Axis Mono-Block Bridge Saw.

Machine with compact dimensions.

Spin of the head 360°.

All the Axis drivers complete with elevated inertia BRUSHLESS motors.

Complete CNC control with Touch screen panel.

Depliant| Technical Specifications | ||

|---|---|---|

| X-axis biade stroke | mm | 3600 |

| Y-axis bridge translation | mm | 1950 |

| Max. Ø biade | mm | 625 |

| Biade holder shaft Ø | mm | 50 |

| Minimum Ø of flanges | mm | 185 |

| Z-axis maximum cutting depth (with 625 Ø disc) | mm | 200 |

| Z-axis max. vertical stroke | mm | 360 |

| A-axis max. head inclination | degree | 90° |

| C-Axis rotation of the head | degree | ±360° |

| Motor power at 1450 revs. (S1) | HP-kW | 15 - 11 |

| X-axis max. speed | m/min | 40 |

| Y-axis max. speed | m/min | 40 |

| Z-axis max. speed | m/min | 3 |

| Voltage/Frequency | V/Hz | 400/50 |

| Weight | kg | 5500 |

| Overall dimensions installed | mm | 6000x3500x3000 |

| Transport | 20' open to container |