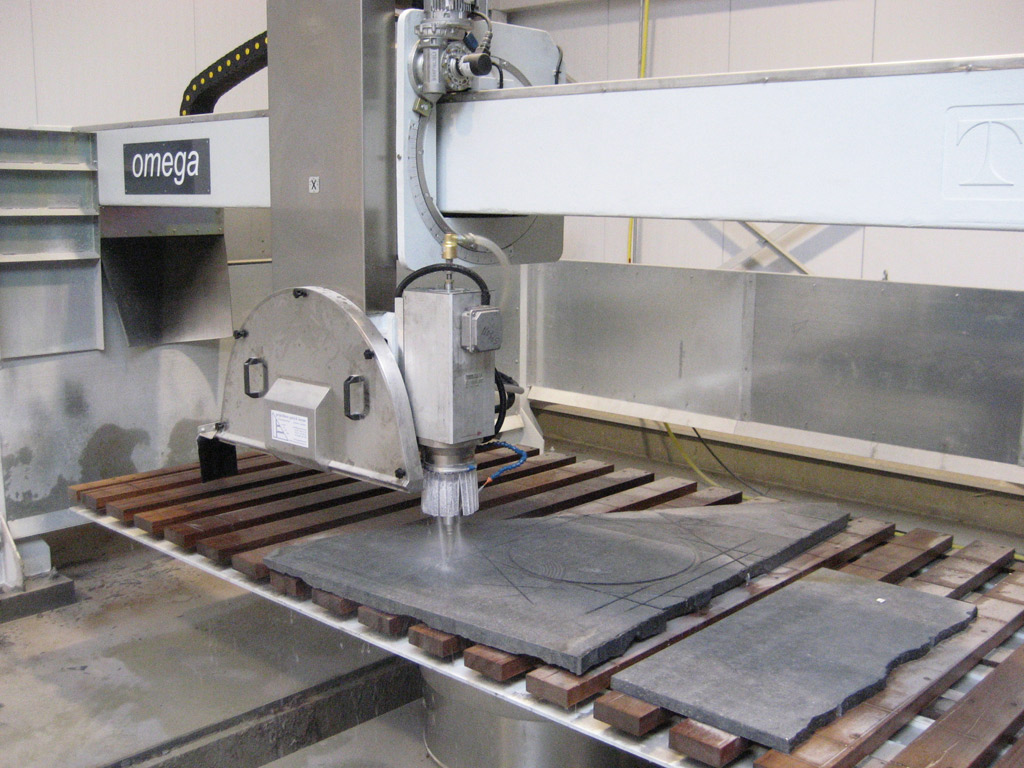

- Main frame bench in highly resistant cast for stability/reduced vibration.

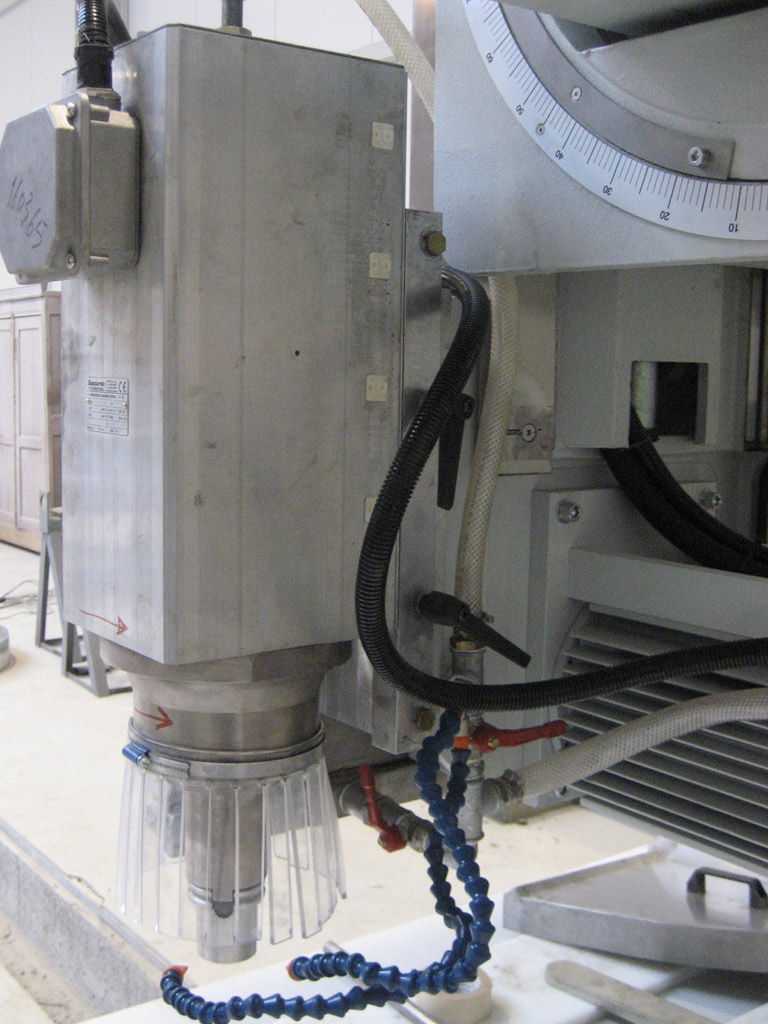

- Motor of reduced dimensions connected directly to disc.

- Electronically controlled inverter all required speeds (optional)

- Blade head slide on recirculating ball on guides in hardened steel in the bridge, powered electrically and managed by inverter, to set right speed, and controlled by encoder.

- Operating head vertical movement obtained by auto-braking motor controlled by encoder on prismatic guide coupling and recirculating ball screw.

- Motorised rotating bench blockable in any position, 0°-360°.

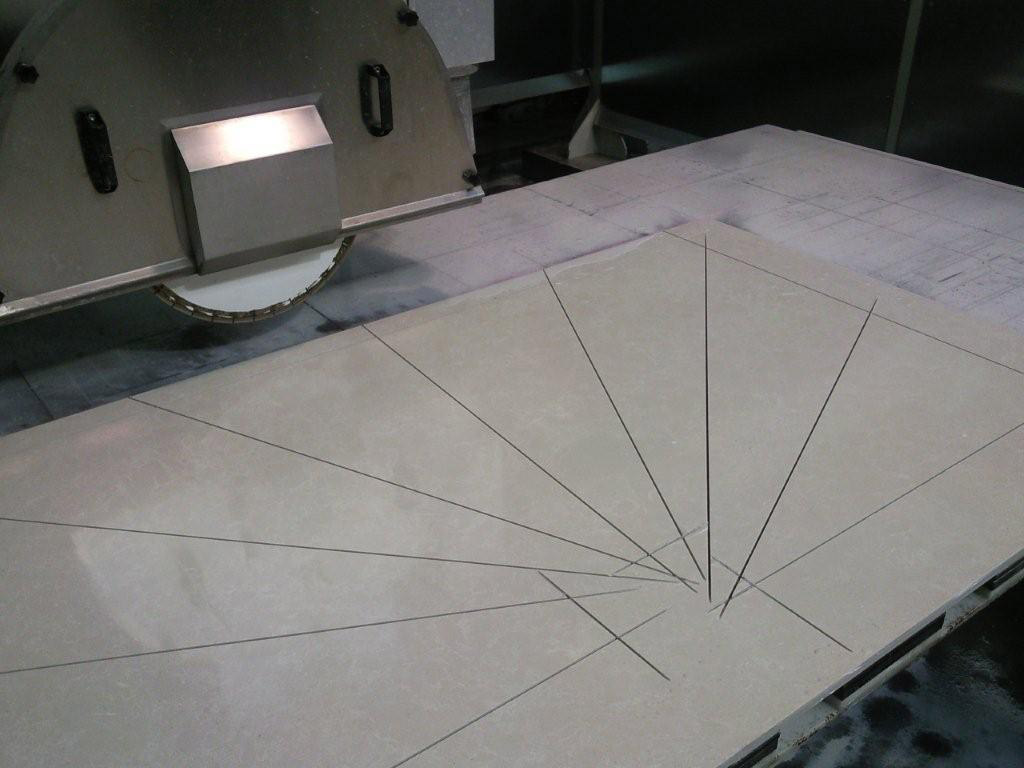

- Electrical tilting head from 0°-90° for marble/granite cutting, even in small steps.

- Sealed electrical board outside foundation wall, where remote control is housed.

- Control panel arm with LCD graphics monitor to view data (optional).

- Right/left movement, translation of bridge, up/down movement of head, bench rotation manually controlled. Separate amper-mometer for regulating right/left sliding speed.

- Soundproofed disc guard.

- Electronic adjustment of cutting/return limit switches for operating head and programme setting.

- CAD drawn profiles and shapes can be carried out with concav/convex shaping and circular cutting (optional).

- Serial RS 232 connection (optional).