- Main structure covered in electrowelded steel sheets.

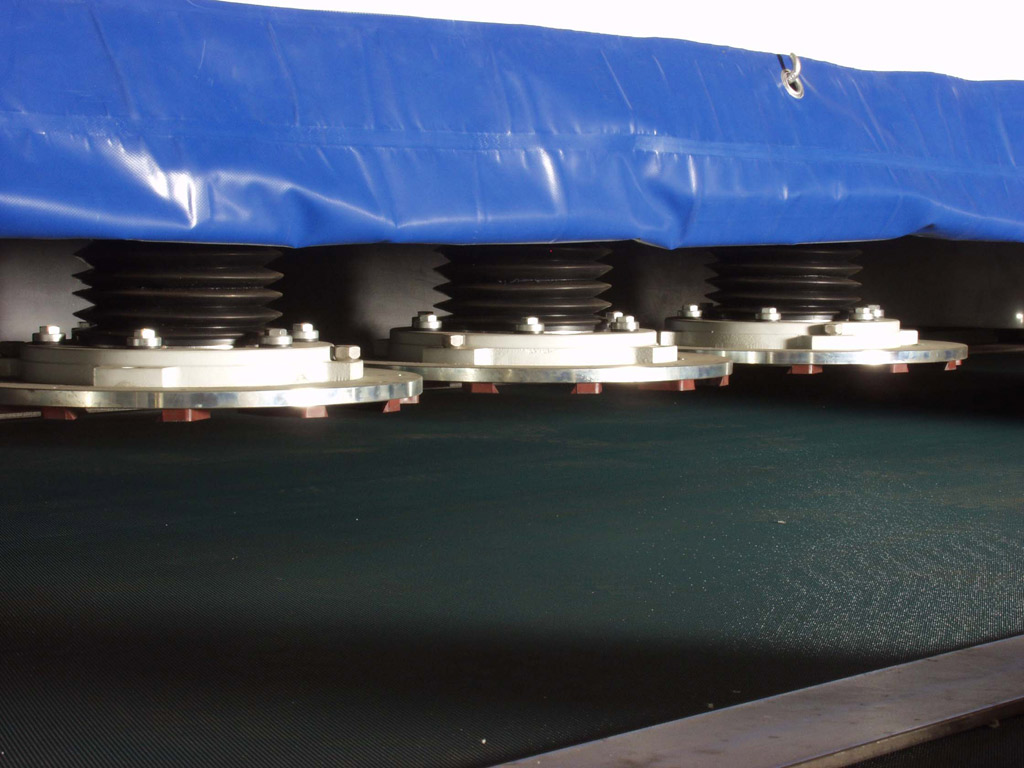

- Conveyor belt seated on level surface, covered in stainless steel.

- Belt runs on two cylinders – one at entrance to stretch belt, one at exit with electronically controlled variable speed gear motor.

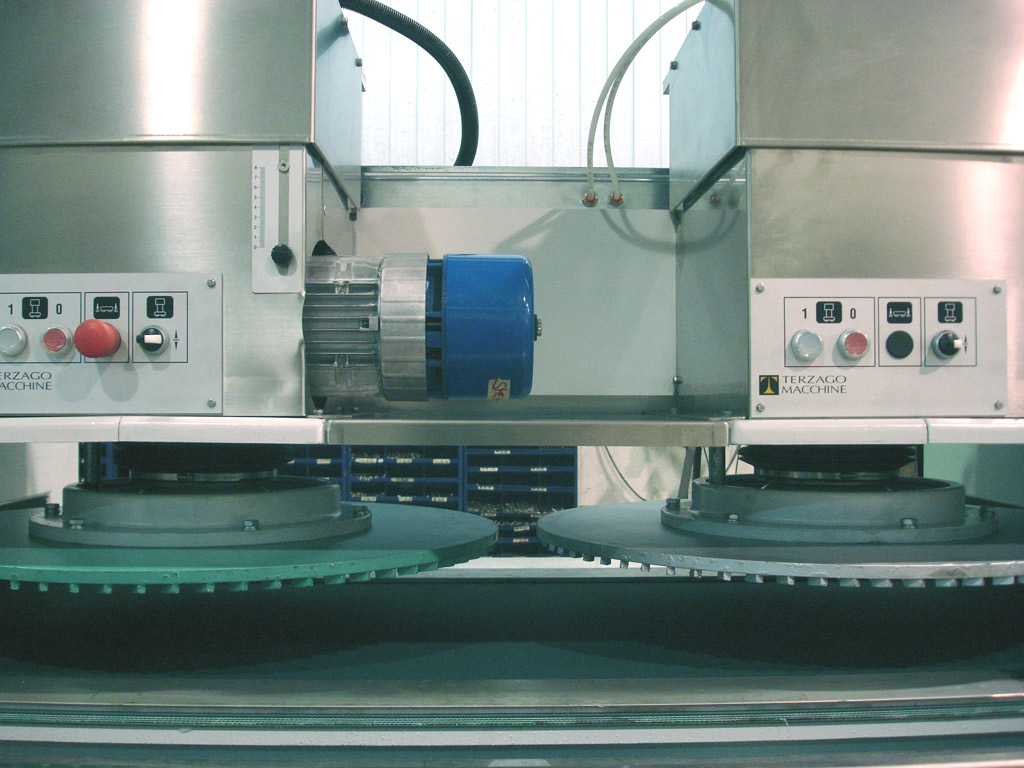

- Operating heads centrally housed on strong, electrowelded beam.

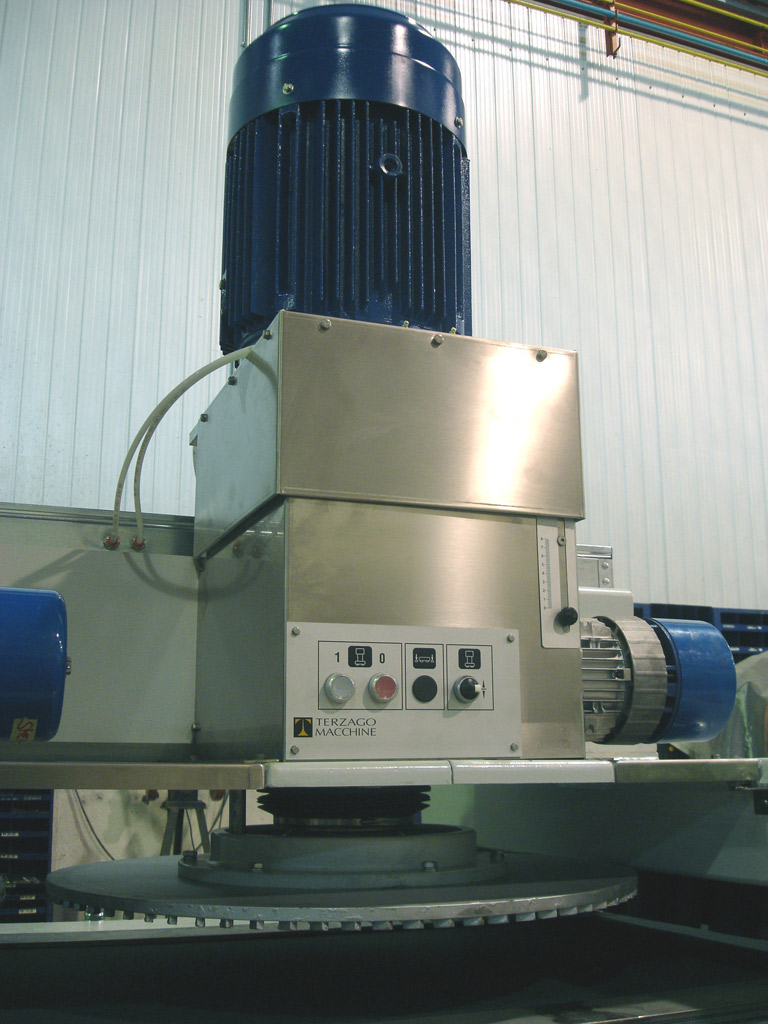

- Pneumatic vertical movement on chrome column.

- Transverse spindle unit beam movement powered by electronically controlled electric motor.

- Beam at front bearing diamond calibrating heads.

- Abrasive/calibrating head up/down movement is pneumatic; working pressure of individual heads can be regulated and seen on pressure gauge; automatic gauging of material thanks to electronic programmer for time/position.

- Individual heads can be excluded.

- Conveyor speed/spindle-holder beam on display in real time; motor absorption.

- Fault-detection.

- Individual heads with raising device for abrasive wear irrespective of material thickness.

- LX board, placed away from main body of machine, provides power, auxiliaries, accident protection and PLC.

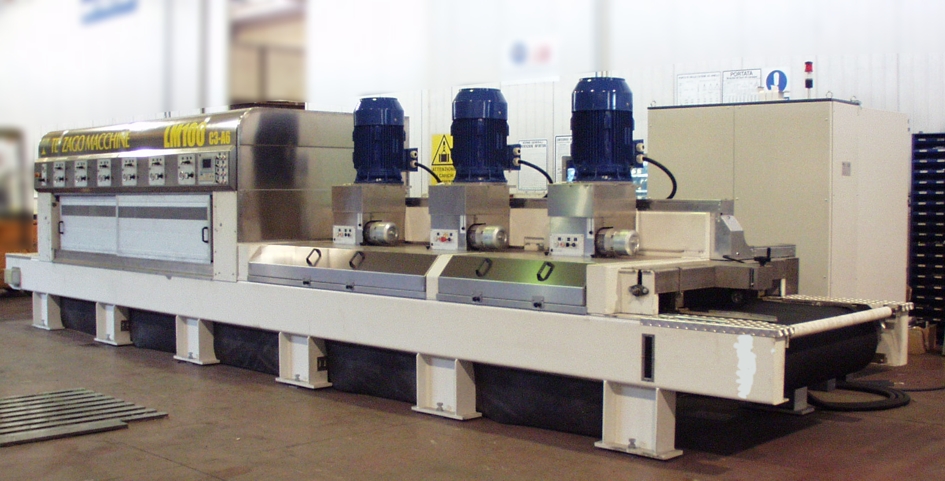

Polishing-Calibrating LM 65

LM 65 – Calibrating Polishing Machine For Marble.

Machine suitable for calibrating and polishing semi-worked strips and/or sized pieces in marble or similar stones.

Machine base in electrowelded steel plates with fully worked top covered and protected by stainless steel covering over which conveyor belt passes.

Up/down movement automatic as material passes thanks to electronic programmer to set lenght of time and position.

The machines are built on specific request of customers matching any kind of polishing process or any kind of natural stone.

Depliant| Technical Specifications | C1 A6 | C2 A8 | C2 A10 | C3 A12 | |

|---|---|---|---|---|---|

| Min/max polishing width | mm | 250/650 | 250/650 | 250/650 | 250/650 |

| Min/max polishing depth | mm | 10/80 | 10/80 | 10/80 | 10/80 |

| Calibrating shaft | n° | 1 | 2 | 2 | 2 |

| Abrasive shaft | n° | 6 | 8 | 10 | 12 |

| Diameter calibrating plate | mm | 750 | 750 | 750 | 750 |

| Diameter abrasive plate | mm | 450 | 450 | 450 | 450 |

| Abrasive shaft motor power | KW | 5,5 | 5,5 | 5,5 | 3x7,5 9x5,5 |

| Calibrating shaft motor power | KW | 18,5 | 18,5 | 18,5 | 18,5 |

| Belt motor power | KW | 1,1 | 2 | 2,2 | 3 |

| Beam motor power | KW | 2,2 | 3 | 3 | 4 |

| Total motor power | KW | 56 | 87 | 98 | 140 |

| Belt speed | m/min | 0 - 3,5 | 0 - 3,5 | 0 - 3,5 | 0 - 3,5 |

| Water requirement | l/min | 1007 | 160 | 200 | 250 |

| Machine length | mm | 6500 | 9000 | 10300 | 12000 |

| Machine width | mm | 1650 | 1650 | 1650 | 1650 |

| Total width | mm | 2100 | 2100 | 2100 | 2100 |

| Height | mm | 2150 | 2150 | 2150 | 2150 |

| Weight | KG | 7700 | 8600 | 10600 | 11200 |

| Standard Equipment | C1 A6 | C2 A8 | C2 A10 | C3 A12 | |

|---|---|---|---|---|---|

| Multifunction programme | n° | 1 | 1 | 1 | 1 |

| Abrasive holder plate | n° | 6 | 8 | 10 | 12 |

| Diamond ring | n° | 1 | 2 | 2 | 3 |

| Abrasive finished device | n° | 6 | 8 | 10 | 12 |