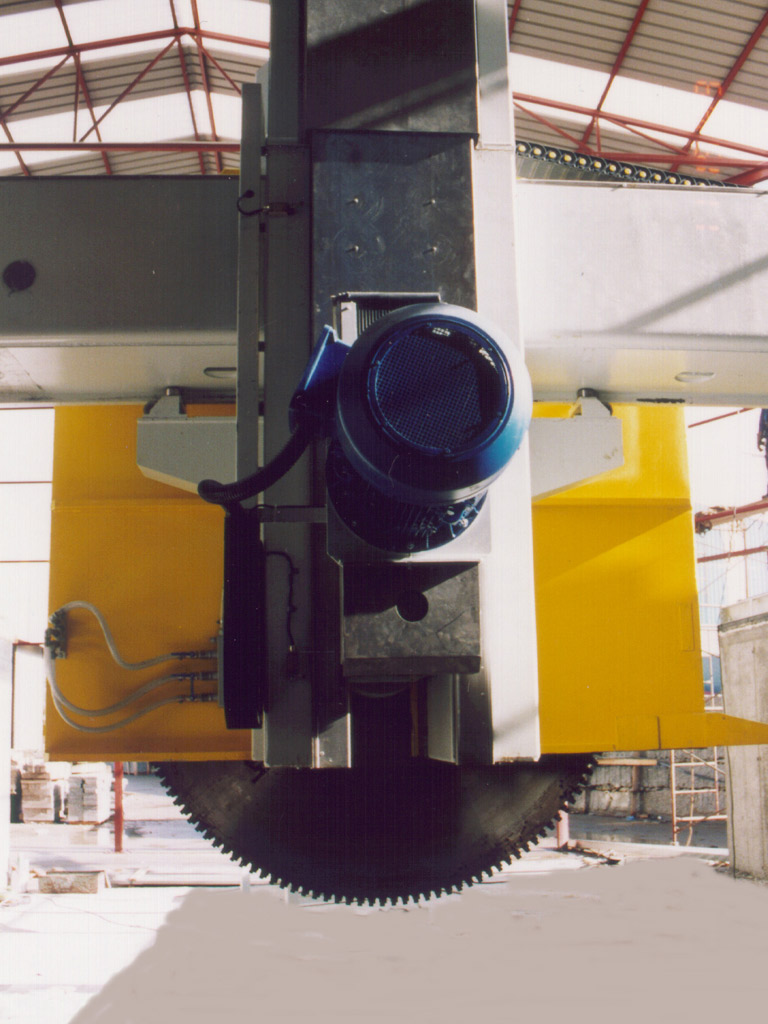

- Built in welded steel with giant blade for extra cutting depth, a robust machine built on two columns that support and guide the vertical cutting unit movement along the cast iron bridge.

- Manual setting of limit switches avoided because of encoder for setting cutting length.

- Rev. variator and encoder for cutting unit traverse. Different cutting depths can be set from terminal.

- Blade-head unit moved horizontally by servomotor coupled to gear motor and rack and pinion system.

- Speed electronically regulated from control panel.

Vertical movement on two precision screws with two worm screws.

Two counter-screws for safety.

One-speed step-cutting motor for rotation of screws which are synchronised by connecting shaft; encoder for positioning. - Main transmission by high performance tracks with oil-bathed gear box.

Shaft rev. changes by pulley (standard) or rev variator (optional). - Centralised lubrication. IP 55 electrical cabinet. Control panel with keyboard and real-time display of operator instructions, alarms and operating parameters.

T35 SE

Giant Blade Saw.

Two strong welded steel columns support and guide vertical movement of bridge of large dimensions made in special cast iron.

Structure given added stability/reduced vibration/less resonance thanks to ribs in cast iron.

Depliant| Technical Specifications | ||

|---|---|---|

| Blade longitudinal stroke | mm | 4000 |

| Blade vertical stroke | mm | 2000 |

| Carriage translation in op. | mm | 2000 |

| Block carriage dimensions | mm | 3000x2240 |

| Max. vertical blade diameter | mm | 3500 |

| Max. cutting depht | mm | 1500 |

| Min. blade diameter | mm | 2200 |

| Blade shaft diameter | mm | 110 |

| Adjustable slide forward speed | m/min | 0 -17 |

| Blade motor power | KW | 55 |

| Total auxiliary motors power | KW | 7,5 |

| Water consumption at 3 bar | l/min | 100 |

| Weight | KG | 13800 |

| Standard Equipment | ||

|---|---|---|

| Central lubrication | ||

| N° 1 Motorised carriage - dimensions | mm | 3000x2240 |

| N° 1 Set of rail (4 x 3.00 m.) | mm | 6000 |

| N° 1 Flange couple for blade - dimensions | mm | 450 |

| N° 1 Photocell safety barrier | ||

| N° 1 Set of pulleys | mm | 165 - 362 - 416 |

| Optional Equipment | ||

|---|---|---|

| N° 1 Inverter | ||

| N° 1 Rotating carriage |